A Thermal Transfer Printer is an electronic device for printing text barcodes and graphics etc, on to a wide range of substrates.

How Does Thermal Transfer Work?

The basis of a Thermal Transfer Printer is an electronic print head containing an array of tiny heating elements. The print head elements generate enough heat to release pigment from an impregnated ribbon, which is then pressed on to the substrate to create an image.

Download Pdf

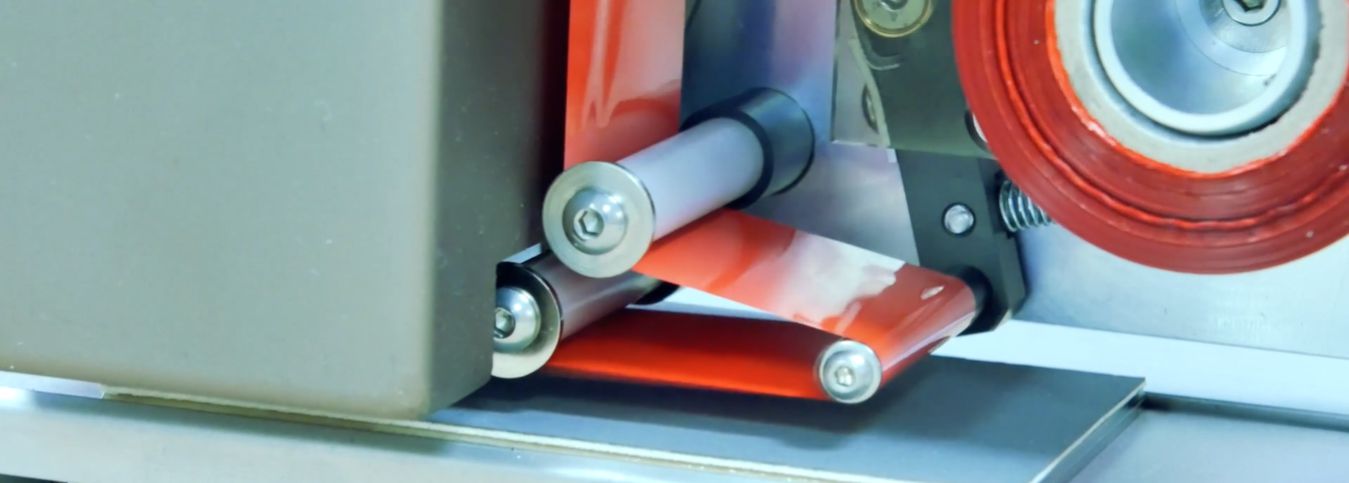

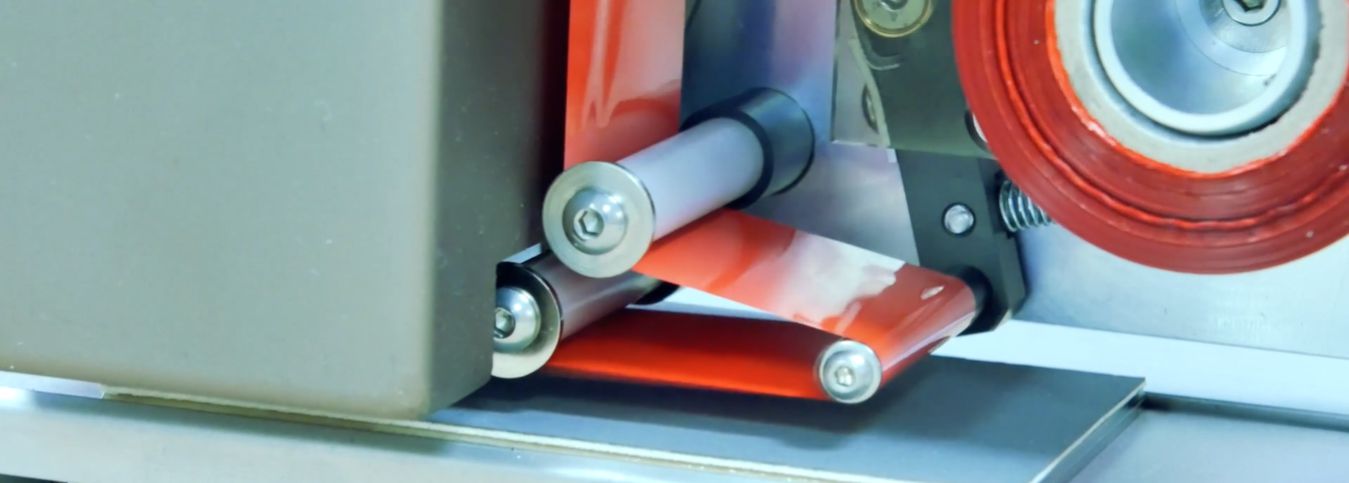

Typical Thermal Application

The printer is ideal for integrating on to most forms of packaging and labelling machinery and in various market sectors including food, pharmaceutical, electronics, automotive etc, in fact anywhere where variable or fixed information is required.

Contact Coding

Contact Coding